AI Boosts 3D Printing Efficiency for Complex Structures

Researchers at Washington State University have developed a self-improving AI algorithm that significantly enhances the efficiency of 3D printing for intricate structures. This groundbreaking method, detailed in the journal *Advanced Materials Technologies*, could revolutionise the use of 3D printing across diverse fields, from medical applications to advanced electronics.

The study focused on optimising the production of complex, lifelike organ models for surgical training and implant testing. These models require precise replication of intricate anatomical features, including veins, arteries, and internal structures, presenting a significant challenge for traditional 3D printing techniques.

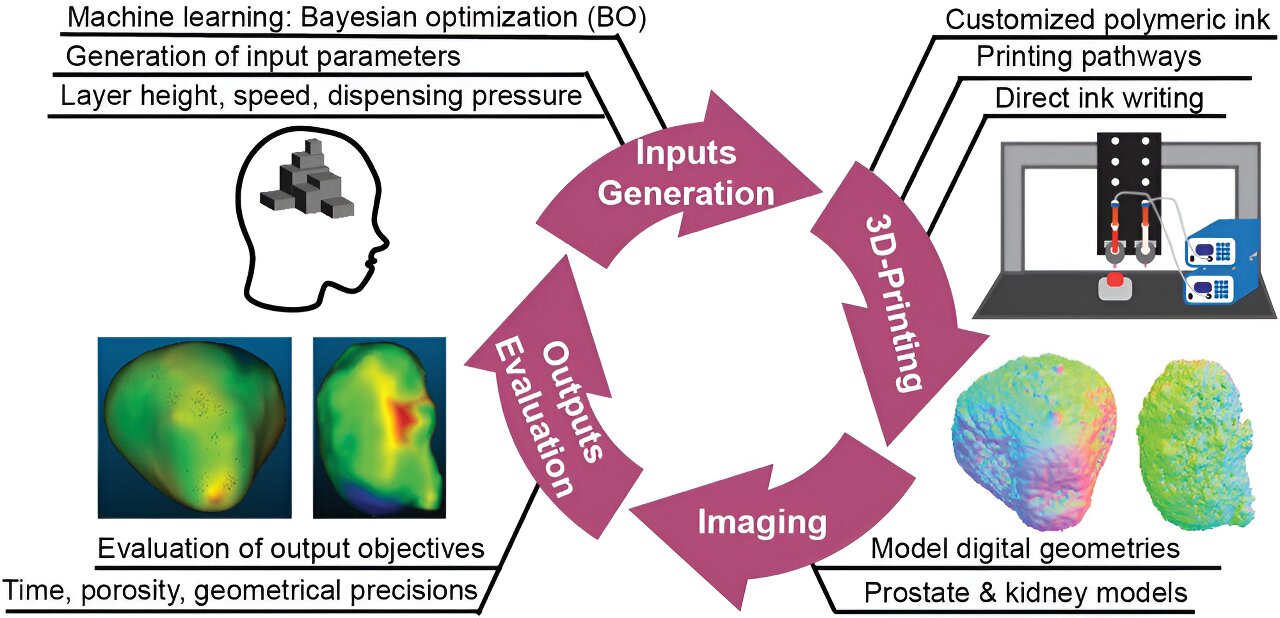

The team employed a powerful AI technique called Bayesian Optimisation to identify and refine the ideal printing settings for these complex structures. This algorithm, trained on a dataset of printed organ models, learns to balance multiple objectives simultaneously, such as geometric accuracy, density, and printing time.

"The sheer number of potential printing parameters is overwhelming," explains Jana Doppa, co-corresponding author and Professor of Computer Science at WSU. "Our algorithm allows us to explore this vast parameter space efficiently and identify the optimal settings for any given design."

In their experiments, the researchers successfully optimised the printing of both prostate and kidney models, achieving remarkable improvements across all key performance indicators. The algorithm automatically generated 60 iterations, progressively refining the printing process to achieve the best possible balance between geometric accuracy, porosity, and printing time.

"This AI-driven approach represents a significant leap forward for 3D printing," says Kaiyan Qiu, co-corresponding author and Assistant Professor of Mechanical and Materials Engineering at WSU. "It saves time, cost, and effort while achieving unprecedented levels of precision in the final product."

The researchers highlight the versatility of their algorithm, suggesting that it can be readily adapted for other 3D printing applications, even beyond biomedical engineering. "The algorithm's ability to optimise multiple objectives makes it ideal for manufacturing various complex structures, from wearable devices to intricate aerospace components," Qiu adds.

This breakthrough promises to democratise access to advanced 3D printing techniques, enabling researchers and engineers to tackle increasingly challenging design problems with greater efficiency and precision. The development of this self-improving AI algorithm marks a significant step towards the future of additive manufacturing, opening up new possibilities for innovation across diverse industries.