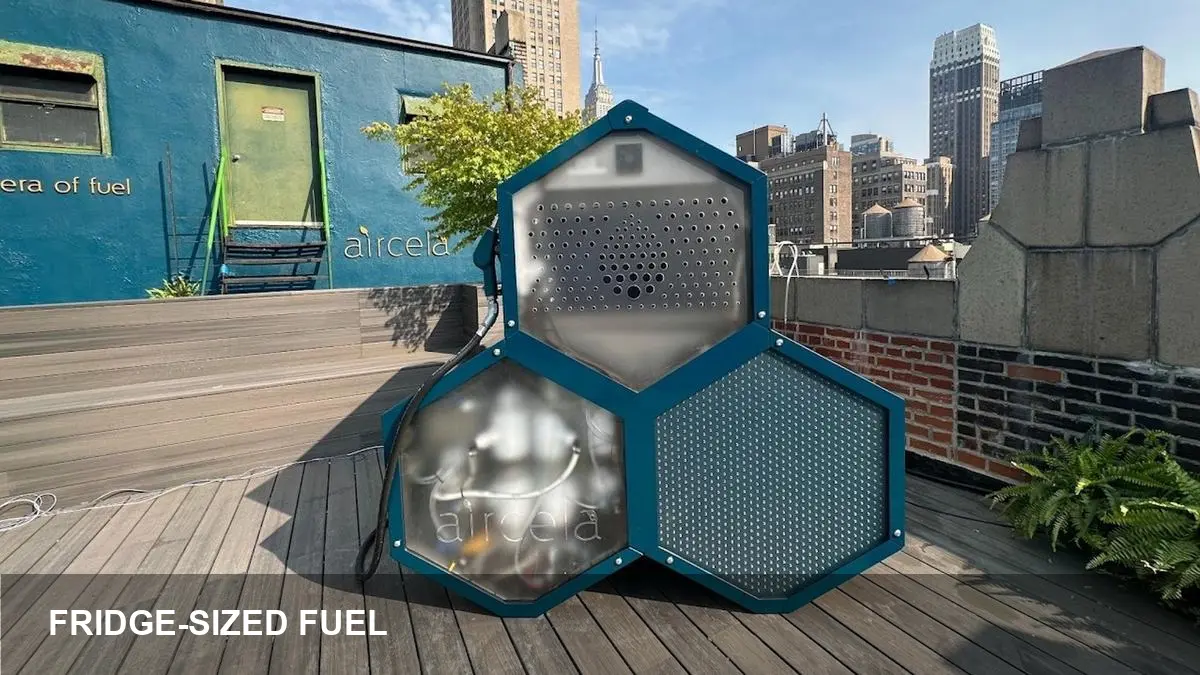

Aircela’s Fridge-Sized Device Turns Air Into Gasoline

- A New York startup, Aircela, has built a fridge-sized machine that converts ambient air into gasoline.

- The system is not “free energy”: it requires significant inputs and energy to produce fuel, but can be practical for small-scale uses.

- Potential applications include decentralized fuel supply for remote sites, research, and backup power where conventional logistics are difficult.

- The device highlights a growing interest in on-site fuel synthesis and air-to-fuel technologies.

What Aircela built

Aircela, a startup based in New York, has developed a compact appliance — roughly the size of a household refrigerator — that turns air into gasoline. The claim centers on capturing components from ambient air and converting them into hydrocarbon fuel in a compact, standalone unit.

The form factor is notable: instead of industrial-scale plants, Aircela’s device is intentionally small, suggesting use cases outside of traditional refinery environments.

Why it matters

If practical at useful cost and scale, a machine that synthesizes liquid fuel from air could shift how fuel is supplied to hard-to-reach locations. Smaller units could reduce the need to transport fuel long distances for temporary sites, field work, or emergency response.

The innovation also underscores growing interest in on-site synthesis and modular chemical processes, where compact hardware substitutes for chemical logistics chains.

Limitations and context

The short description makes clear this is not “free energy.” Converting air into gasoline requires significant energy and inputs, which limits the net efficiency and economic case compared with conventional fuel supply.

Practical impacts will depend on the machine’s energy source, production rate, operational cost, and lifecycle emissions. Those details are critical to judging whether the device is competitive or better suited for niche uses.

Practical, small-scale applications

At present, the most plausible uses are small-scale and specialized: supplying fuel for remote generators, research facilities that need on-demand hydrocarbons, or backup systems where resupply is costly or impossible.

For labs and developers, a compact air-to-fuel unit could also serve as a testbed for synthetic-fuel chemistry and process optimization without investing in large pilot plants.

What to watch next

Follow-up items to evaluate the technology will include published performance data, energy consumption figures, cost per liter of fuel produced, and independent emissions assessments. Commercial availability and pilot deployments will indicate whether the idea moves from intriguing prototype to practical product.

Aircela’s fridge-sized apparatus adds a fresh data point to air-to-fuel research, highlighting both the potential and the practical constraints of making gasoline from thin air.