Origami Reimagined: 3D-Printed Compliant Mechanisms

- Key Takeaways:

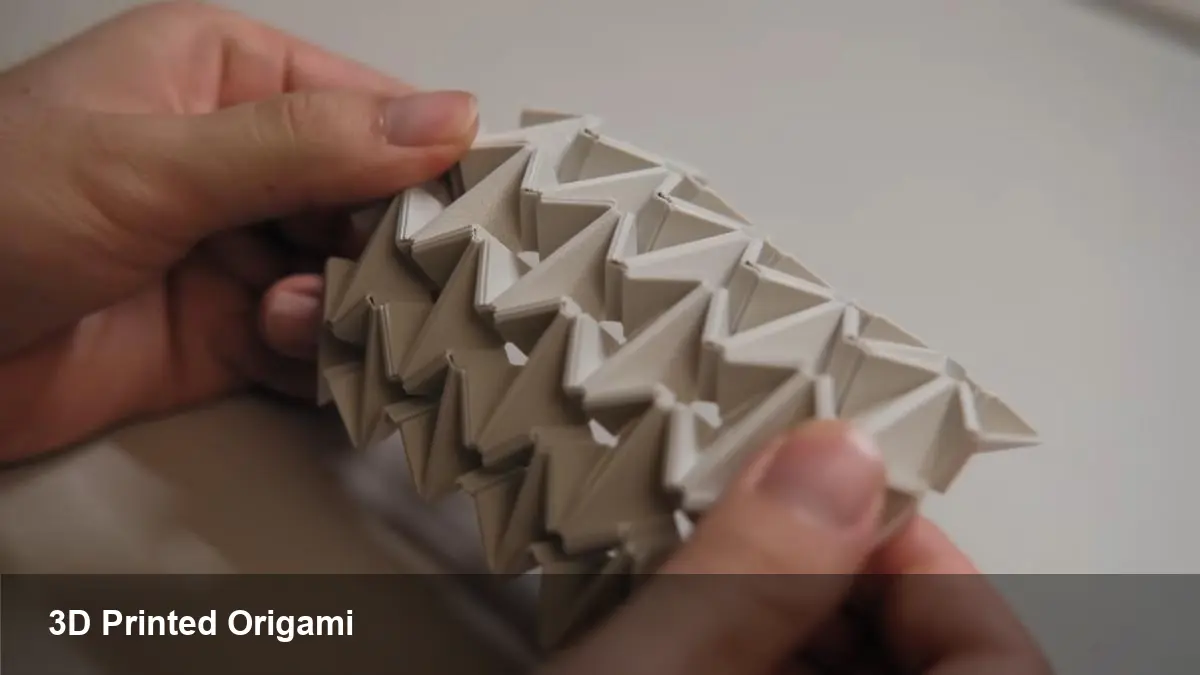

- Designer Matthew Lim adapts traditional origami into 3D-printed compliant mechanisms by thinning crease lines and offsetting panels.

- Simple crease-thinned sheets work for basic folds, but complex designs require offset-panel techniques to avoid failure.

- Offset panels let designers use thicker, stiffer faces while keeping reliable fold lines, enabling twisting and contracting mechanisms.

What Hackaday reported

Ian Bos at Hackaday highlighted a small but important advance in 3D-printed origami on December 21, 2025. The piece covers the work of maker and designer Matthew Lim, who has been exploring how fold geometry and print detail can produce functional compliant mechanisms directly from a 3D print.

How the technique works

Lim starts by translating basic origami folds into thin 3D-printed sheets where the crease lines are printed thinner than the panels. That contrast makes the flat areas stiff while leaving the creases flexible enough to bend reliably.

This approach preserves the elegant minimalism of origami while letting a single printed part provide both structure and motion without hinges or assembly. The result is a compliant mechanism that uses material and geometry instead of separate moving hardware.

Problems with complex folds and the offset-panel fix

For simple folding patterns the thin-crease method performs well, but more elaborate geometries overstress the crease areas and can lead to early failure. Lim found that when adjacent creases interact the thin lines become weak.

To address this, he borrowed an idea from prior research: placing folds on alternating sides of adjacent panels and using offset paneling. Offsetting the panels preserves fold function while letting faces be printed thicker and stiffer. The change reduces strain at crease intersections and allows more ambitious, load-bearing fold geometries.

Demonstrations and designs

Beyond flat-fold experiments, Lim tested compliant-mechanism-focused prints such as twisting cylinders that contract when actuated. These examples show the technique can produce complex motion profiles — contraction, twist, and multi-axis bending — from a single printed part.

Watch Lim’s demonstration and build examples on his video: https://www.youtube.com/watch?v=FNVBK7-h9Fs

Why this matters for designers and makers

Converting origami principles into reliable 3D-printed parts expands what hobbyists and engineers can build with FDM and resin printers. The offset-panel strategy in particular lets creators retain the advantages of origami — simplicity, reduced part count, and efficient geometry — while improving durability.

As additive manufacturing evolves, these hybrid geometry/print techniques will likely inspire new lightweight mechanisms, deployable structures, and consumer devices that rely less on assembly and more on a single printed geometry.