Phonon Laser Could Make Smartphone Chips Smaller, Faster

- Key Takeaways:

- Engineers built an electrically injected surface acoustic wave (SAW) phonon laser on a single chip, producing vibrations at ~1 GHz and scalable to tens or hundreds of GHz.

- The device combines silicon, lithium niobate and indium gallium arsenide to convert electrical current into amplified surface vibrations.

- A single-chip SAW laser could replace multiple components in phone radios, enabling smaller, faster and lower-power wireless hardware.

- Research led by Matt Eichenfield (CU Boulder) with teams at University of Arizona and Sandia National Laboratories was published in Nature.

What the team built

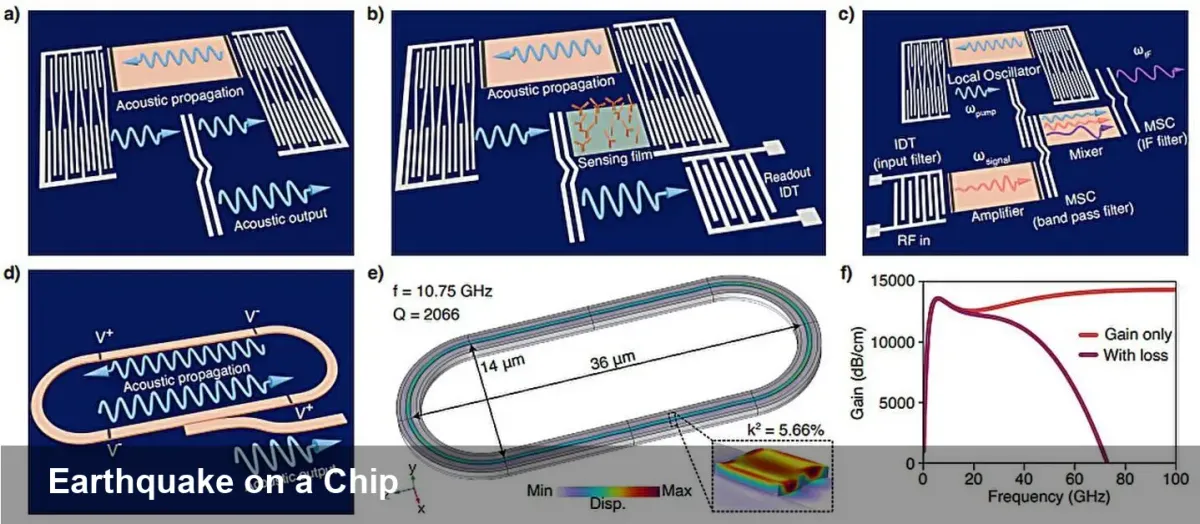

Researchers developed a compact “phonon laser” that generates surface acoustic waves — tiny, localized vibrations that travel only across a material’s surface. The bar-shaped device is roughly half a millimeter long and integrates a silicon substrate with a thin lithium niobate piezoelectric layer and a nanoscale sheet of indium gallium arsenide.

The stack lets mechanical surface waves in lithium niobate interact directly with electrons in the indium gallium arsenide. An injected electric current accelerates electrons, which in turn amplify the surface waves in a feedback loop similar to an optical diode laser.

How it works: laser behavior, but for vibrations

The device creates SAWs that bounce between reflectors on the chip, gaining energy on each forward pass and partially leaking out as a usable output. Lead author Alexander Wendt described the effect as “almost like the waves from an earthquake, only on the surface of a small chip.”

Unlike conventional SAW setups that require two chips and external drivers, this phonon laser operates with an electrical injection on a single chip and a simple power source such as a battery.

Performance and frequency potential

The team demonstrated SAW generation near 1 GHz and argue the approach can scale well beyond the ~4 GHz practical limit of many current SAW components. They anticipate pushing frequencies into the many tens or even hundreds of gigahertz, which would support higher-bandwidth RF filtering and signal processing.

Higher SAW frequencies translate to smaller acoustic wavelengths and therefore physically smaller filters and resonators — a direct path to size and power reductions in RF front-ends.

Why this matters for phones and wireless gear

Surface acoustic wave components are already embedded across modern radios: in cellphones, GPS, key fobs and radar. Today’s radios route signals through multiple discrete SAW filters and chips; a single-chip SAW laser could consolidate those functions and reduce component count.

Matt Eichenfield, senior author and Gustafson Endowed Chair in Quantum Engineering at CU Boulder, said the team can “literally make every component that you need for a radio on one chip using the same kind of technology.” That consolidation promises lower cost, lower power consumption and smaller device footprints for future smartphones and wireless systems.

Next steps

The researchers aim to increase operating frequency, optimize material stacks and integrate additional radio functions on-chip. If successful, the phonon laser could reshape RF design for consumer and industrial wireless hardware.