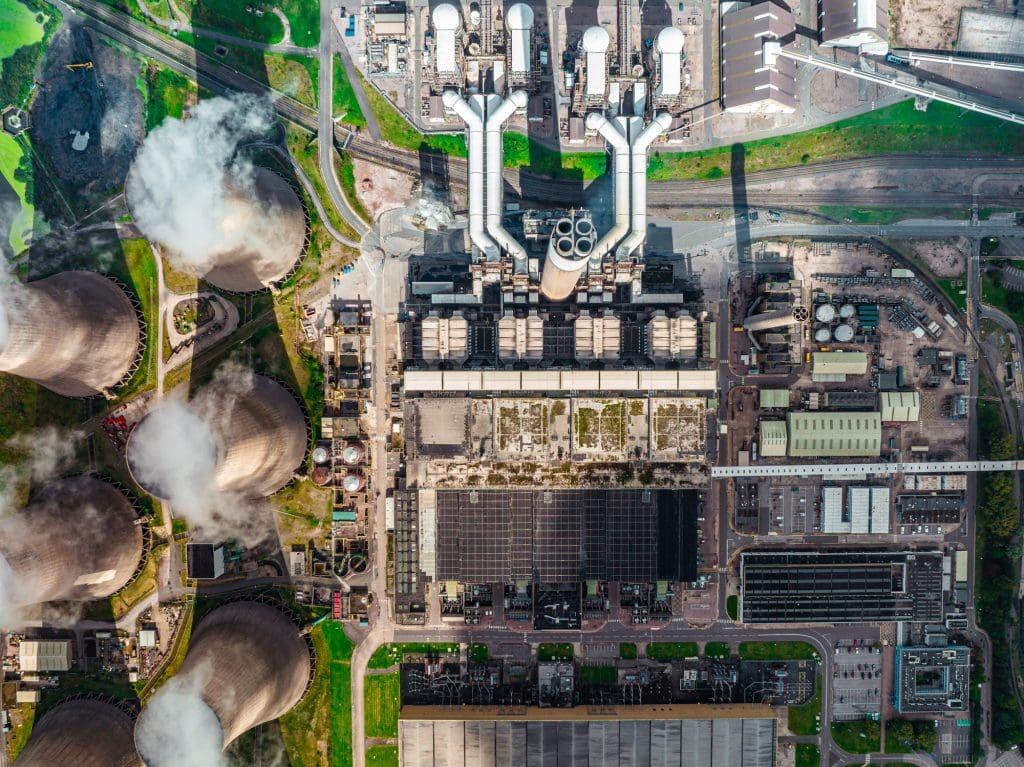

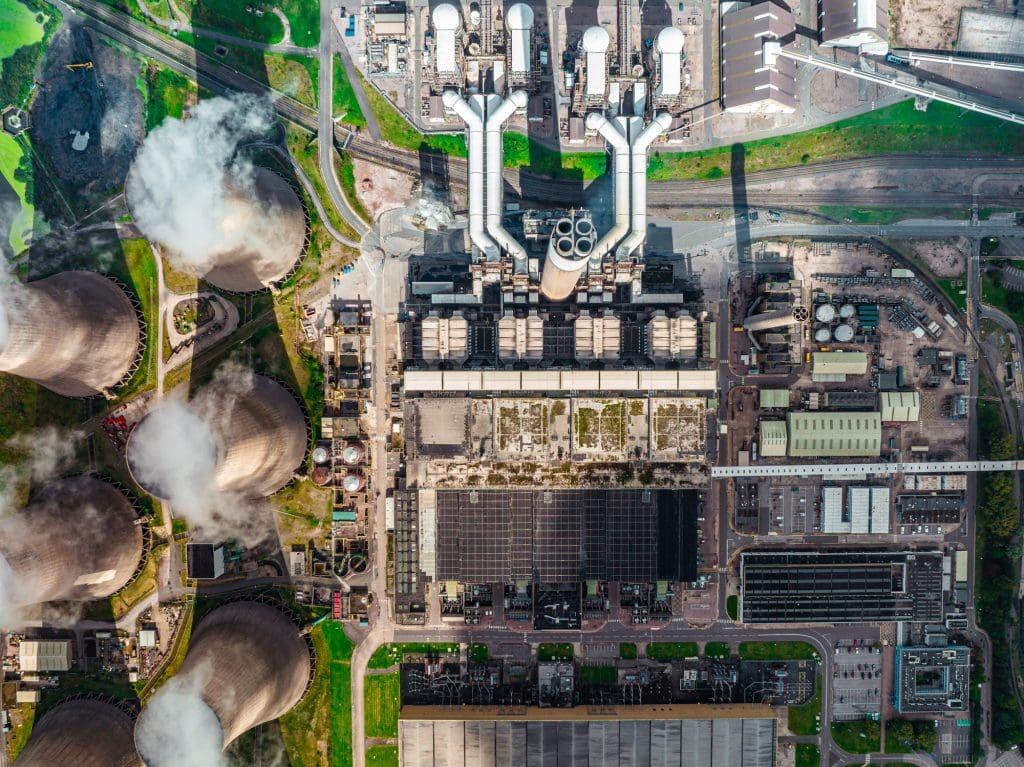

Carbon Clean, a leading innovator in carbon capture technology, has announced the development of its Cyclone CC C1, a groundbreaking modular design poised to revolutionise the industry. This innovative system promises significant improvements in efficiency, space utilisation, and sustainability compared to traditional carbon capture plants.

The Cyclone CC C1 is designed to capture carbon dioxide concentrations ranging from 3% to 20%, with a projected annual capture capacity of up to 100,000 tonnes of CO2. Its modular nature offers considerable advantages. Unlike conventional carbon capture plants, which often require extensive space and complex infrastructure, the Cyclone CC C1's compact design significantly reduces both its footprint and the amount of equipment needed. This streamlined approach contributes to lower construction costs and simplifies deployment.

Central to the system's efficiency is its innovative use of rotating packed bed technology. This replaces the large, vertically oriented columns found in traditional plants. This technological shift results in a remarkable 70% reduction in the average height of the carbon capture equipment, translating to substantial savings in construction materials and land requirements. Furthermore, the design necessitates 35% less steel than conventional systems, bolstering its overall environmental credentials.

The UK government's substantial investment of £21.7 billion in carbon capture technology over the next 25 years underscores the nation's commitment to tackling climate change. The Cyclone CC C1 exemplifies the type of innovative solutions needed to meet these ambitious targets.

Prateek Bumb, Carbon Clean's co-founder and chief technical officer, explained the technology's underlying principles: "It's a centrifuge rotating at high speeds, up to 200 or 300 rotations per minute. By utilising centrifugal force, we dramatically increase mass transfer efficiency. This allows us to achieve what would normally require a 40-metre-high system within a much more compact design."

Bumb highlighted the ambitious timelines for deployment: "Currently, we can deliver the product within 18 months. However, with the right ecosystem in place â efficient supply chains, mass production, and standardisation â we aim to reduce this to under six months. We're striving to create a decarbonisation and delivery ecosystem, learning from the successes of the electric vehicle and solar industries in terms of mass production and standardisation."

He further emphasised the crucial role of sustainable carbon capture solutions: "Sustainability and carbon capture are intrinsically linked. Industries like cement, steel, fertiliser, and oil and gas â sectors notoriously difficult to decarbonise â urgently require sustainable solutions. We believe our approach offers the most optimal and sustainable pathway to decarbonisation, aligning perfectly with the broader roadmap for achieving net-zero emissions." The Cyclone CC C1 represents a significant leap forward in carbon capture technology, offering a potentially transformative solution for industries striving to reduce their environmental impact. Its modular design and impressive efficiency gains position it as a key player in the global fight against climate change.

Article

Business

Revolutionary Modular Carbon Capture Design Unveiled