The market for conductive polymer capacitors is experiencing rapid growth, driven by the increasing demand for miniaturised electronics and the rise of electric vehicles. This market is expected to reach £28.8 billion by 2031, growing at a compound annual growth rate (CAGR) of 11.5% from 2024.

What's Driving This Growth?

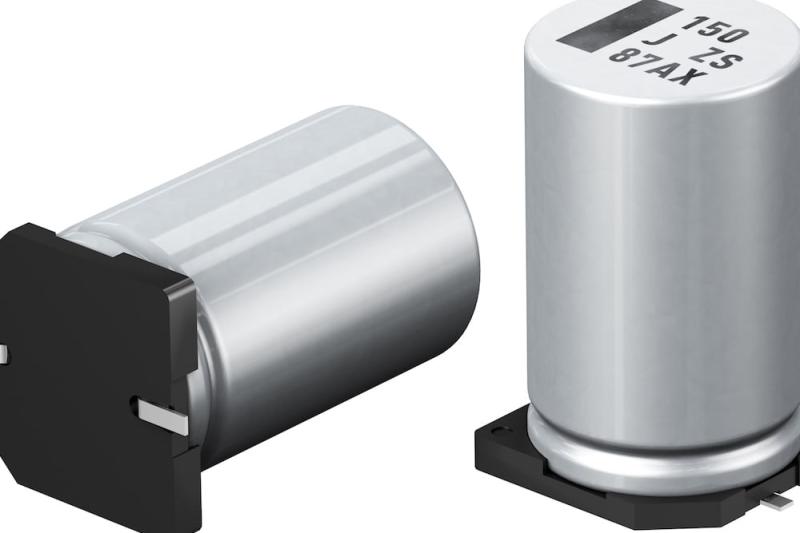

The miniaturization trend in consumer electronics, alongside the increasing popularity of electric vehicles, is fuelling the demand for solid-state capacitors with high energy density and compact designs. Conductive polymer capacitors are particularly well-suited for these applications due to their integrated design and long lifespan.

The rise of renewable energy sources like solar and wind power is another key driver. These sources require reliable energy storage technologies, and conductive polymer capacitors offer high power density, long cycle life, and reliable performance, making them ideal for this sector.

The Electrification of Vehicles:

As the automotive industry transitions towards electric vehicles, the demand for advanced energy storage technologies is growing. Conductive Polymer capacitors excel in this sector due to their high power output for acceleration and regenerative braking, as well as their long service life and reliability. This makes them suitable for applications like start-stop systems, infotainment modules, and battery management systems in electric vehicles.

Technological Advancements:

Constant research and development in materials like PEDOT and PPY, alongside advancements in manufacturing processes, are addressing some of the challenges associated with conductive polymer capacitors. Bio-inspired materials and self-healing polymers are enhancing the stability, lifespan, and cost-effectiveness of these capacitors. Additive manufacturing and 3D printing allow for complex multi-layer designs, while roll-to-roll processing offers higher throughput. These innovations are expanding the potential applications of conductive polymer capacitors, driving their adoption across various industries.

Key Players in the Market:

Several prominent companies are leading the way in the conductive polymer capacitor market, including:

Panasonic

Murata Manufacturing

Nichicon Corporation

Rubycon Corporation

Kemet Corporation

Elna Co., Ltd.

Vishay Intertechnology

United Chemi-Con

Taiyo Yuden Co., Ltd.

Eaton Corporation

AVX Corporation

WIMA Capacitors

Cornell Dubilier Electronics

BHC Components

CDE (Cornell Dubilier Electronics)

Nippon Chemi-Con

Fujitsu Component Limited

KEMET Electronics Corporation

Sanyo Electric Co., Ltd.

Aihua Group

Market Segmentation:

The conductive polymer capacitor market can be segmented by product type and applications:

By Product Type:

Electrolytic Capacitors

Non-Electrolytic Capacitors

Other Types

By Applications:

Consumer Electronics

Automotive

Industrial Equipment

Telecommunications

Others

Key Regions:

The market is experiencing growth across various regions, including:

North America (U.S., Canada, Mexico)

Europe (Germany, U.K., France, Italy, Russia, Spain, Rest of Europe)

Asia-Pacific (China, India, Japan, Singapore, Australia, New Zealand, Rest of APAC)

South America (Brazil, Argentina, Rest of SA)

Middle East & Africa (Turkey, Saudi Arabia, Iran, UAE, Africa, Rest of MEA)

The Future of Conductive Polymer Capacitors:

The conductive polymer capacitor market is poised for continued growth as the demand for miniaturised electronics and electric vehicles intensifies. Advancements in materials and manufacturing processes will continue to drive innovation and expand the applications of these capacitors. The future looks bright for this burgeoning market, promising a significant contribution to the advancement of electronics and sustainable energy technologies.